Highly Potent API (HPAPI) Handling: An Expert Interview with Judy Cohen

Highly potent APIs (HPAPIs) are a rapidly growing segment of the pharmaceutical industry. More than 1,000 small molecule highly potent drug products are currently in development, and market estimates project close to 10% annual growth in this space. However, HPAPIs have strict handling requirements that require high capital investment and specialized personnel to develop. As a result, many HPAPI investigators turn to CDMOs like Particle Sciences who have the facilities, equipment, and personnel in place to take their HPAPI project through development and manufacturing.

Judy Cohen, Vice President of Quality Assurance at Particle Sciences, is an expert in HPAPI handling procedures, having worked on dozens of highly potent compound projects during her career. We sat down with Judy to discuss her experience with HPAPIs and learn more about the changing requirements and perceptions in this field.

Q: What are Highly Potent APIs (HPAPIs)?

Judy: Highly potent APIs are compounds that elicit a biological response at a very low dose. Traditional examples of HPAPIs are cytotoxic compounds and sex hormones such as estrogen. However, any type of compound can be highly potent if it causes a response at a low dose.

Q: How are HPAPIs Classified?

Judy: There is no standard for the definition of an HPAPI because classification systems vary across companies and regions. The most common methods for classifying these compounds rely on control banding strategies, which categorize APIs based on occupational exposure limits. An occupational exposure limit (OEL) is an upper limit on the acceptable concentration of an API in workplace air. These limits are typically set by toxicologists who factor in data from literature, preclinical/clinical studies, and similar compounds (especially for new chemical entities) to calculate the OEL.

Once an OEL is identified, the API is placed into the appropriate occupational exposure band (OEB), which sets a risk level for the compound and provides guidance on what handling requirements are necessary. Most CDMOs use either a four- or five-band system to classify APIs. In the four-band system, compounds that fall under bands 3 and 4 (OEL < 10 µg/m3) are traditionally considered highly potent and demand special handling requirements (a four-band control table is shown in Table 1).

Table 1: Four Band Occupational Exposure Band Control Table

| OEB | OEL | Suggested Design Controls | Properties |

|---|---|---|---|

| 1 | > 500 µg/m3 | General room ventilation. Conventional open equipment with local exhaust ventilation (LEV). | Compounds that are not harmful and/or have low pharmacological activity. |

| 2 | 10 – 500 µg/m3 | Semi-closed to closed material transfer; laminar flow/directionalized laminar flow, engineered LEV. | Compounds that are moderately toxic and/or have moderate pharmacological activity. |

| 3 | 0.03 – 10 µg/m3 | Transfer using direct coupling and closed systems. Selected use of unidirectional air flow booths. | Compounds that are toxic and/or have high pharmacological activity.* |

| 4 | < 0.03 µg/m3 | Totally enclosed processes; direct coupling transfer; barriers/isolation technology. | Compounds that are extremely toxic and/or have very high pharmacological activity. |

* Chemicals of unknown toxicity which are believed to have the potential for high to extremely high toxicity or pharmacological activity based on its therapeutic class or other indicators will be assigned to OEB 3 by default.

Q: How Does Particle Sciences Prepare to Bring an HPAPI In-House?

Judy: Once we know a new API is going to brought into our facility, we perform a chemical entity assessment. This starts by determining the OEL for a compound. If the API is well-characterized and commercially available, this information has likely already been calculated by toxicology professionals. However, at Particle Sciences, we work with a high number of new chemical entities (NCEs) for which there is no established OEL. In these cases, we look to several information sources to properly assign an OEB:

- Toxicity information from the client

- Literature searches on the API in question or similar compounds

- Preclinical and clinical study results

- Third-party EHS firms staffed by toxicologists and industrial hygienists

When searching for banding information on an API, we look for data on toxicity in humans (or in animals if this data is not available). For example, we seek data on systemic effects (such as weight loss) and whether they are reversible. These distinctions can change the risk level of the API. We check if the compound is classified as a carcinogen by the CDC or IARC, and we also look for fertility effects (teratogenicity and effects on pregnancy) and genotoxicity (AMES testing), among other factors. If there is enough information on the API, we band the compound internally. If not, we work with third-parties who can perform further investigations to assign the proper OEB.

Q: How Do You Develop an HPAPI Containment Strategy?

Judy: Ultimately, the purpose of an OEL or OEB is to establish a safety factor and determine how large the buffer is between “no effect” and “physiological effect” for a given compound. For HPAPIs, this buffer is small, so higher OEBs come with stricter handling guidance. There are essentially two goals to containment of HPAPIs:

- Prevent cross-contamination in a multi-use facility or with multi-use equipment

- Limit employee exposure

Analytical method development is the linchpin of any effective HPAPI containment strategy. Any CDMO that claims HPAPI expertise must have a seasoned staff of analytical scientists to develop validated and sensitive methods for API detection. For example, to measure exposure, we may have our scientists wear special badges that are later analyzed. Without reliable HPAPI detection methods, we would not be able to quantify exposure and ensure our containment strategies are keeping our employees safe. Proper method development also allows us to measure residual API on multi-use equipment and ensure there is no cross-contamination between projects.

When developing a containment strategy, we look at a range of factors that impact the risk to our employees. A critical factor in containment is understanding potential routes of exposure (Table 2). These are impacted by the pharmacokinetics and the physical form of the API as well as how the API is being processed. In general, powder HPAPIs pose the greatest exposure risk because they can be inhaled. An HPAPI that is dissolved in solution or encapsulated may pose less risk because it presents fewer routes of exposure. These risks may also be API-specific. For example, the HPAPI digoxin is readily absorbed through the skin, so avoiding skin contact is critical.

Table 2: Potential Routes of Exposure to Highly Potent APIs

| Route | Potential Source of Exposure |

|---|---|

| Ingestion | Inhalation through mouth or nose |

| Transdermal | Absorption through skin |

| Intramuscular | Accidental puncture |

| Mechanical Transfer Through Mucous Membranes | Residue on clothing or equipment |

| Ocular | Airborne particles |

Q: What are the Critical Considerations Associated with HPAPI Handling?

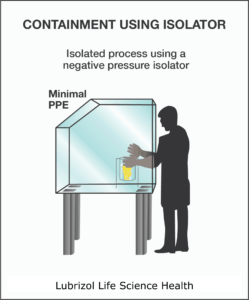

Figure 1: HPAPI containment using an isolator.

Judy: Handling of HPAPIs at Particle Sciences is dictated by a Quality Risk Map, which is a tool that allows you to look at a process stream and assess where the riskiest steps are. From there, you can design containment systems, which typically isolate the HPAPI from the surrounding environment. HPAPI handling usually involves some combination of isolators (soft wall or hard wall, as shown in Figure 1), shrouds, and/or fume hoods. At Particle Sciences, we’ve seen that soft wall isolators are an effective way to build flexibility into a process because they are easy to work with, simple to clean up, and essentially act as a large glove box for containment.

Isolation units are not enough when it comes to HPAPI containment. The surrounding facilities must also be designed to minimize exposure risk. Particle Sciences is a multi-use CDMO, meaning we handle both HPAPIs and lower potency compounds. As a result, we have dedicated cleanroom suites for HPAPIs. These are single pass cleanrooms that run on HEPA in-HEPA out technology, meaning the air in the cleanroom is HEPA filtered coming in and going out. Our HPAPI suites also operate under negative pressure to prevent HPAPI from exiting the cleanroom.

Q: How Are Employees Prepared for Handling HPAPIs?

Judy: A robust training program must be in place to ensure employees are equipped to work with HPAPIs. A proper training program includes teaching employees how to gown properly, which hazards to look for when working with HPAPIs, and how to properly weigh/transfer compounds to minimize exposure risk. Companies may also have universal guidelines in place that educate employees on the standard considerations for OEB 3/4 compounds or specific dosage forms containing HPAPIs (such as aerosolized solutions). At Particle Sciences, we have a hands-on training program that includes exercises on how to properly equip and use PPE such as respirators.

Q: How is the Regulatory Environment Around HPAPIs Changing?

Judy: In recent years, the regulatory environment has become friendlier towards HPAPIs. Historically, we’ve seen a stigma associated with HPAPIs that stems from their strict regulatory requirements. This was especially true in Europe, where there used to be rules that any cytotoxic, sex hormone, or steroid needed to be handled in a standalone HPAPI facility. In recent years, these guidelines have been updated to incorporate an acceptable daily exposure limit based on therapeutic index, creating a more straightforward pathway for multi-use facilities.

In our conversations with the FDA, they’ve also been open to the idea of multi-use facilities and want to discuss containment strategies to enable the handling of both HPAPIs and lower potency compounds under one roof. The growing need for HPAPI handling has sparked global trend towards revising the regulatory environment around highly potent compounds and creating a more appealing development and manufacturing pathway for these drug products.

Q: What Trends Do You See in the HPAPI Industry?

Judy: HPAPIs are becoming a lot more common. Pharmaceutical companies are always looking for ways to stay competitive, often by improving upon what is already on the market. Higher potency drugs have the potential to achieve similar efficacy at a lower dose than other APIs, which is appealing to drug developers because it minimizes patient exposure to medication. In addition, most oncological agents are HPAPIs, and we are seeing an increasing number of clients with those types of compounds.

Q: What is the Most Important Feature a Customer Should Look for in an HPAPI CDMO?

Judy: Experience, experience, experience. There is simply no substitute for experience when it comes to HPAPI handling. At Particle Sciences, HPAPI projects are not intimidating because we’ve dealt with them many times before. We have the equipment and facilities to contain HPAPIs, the analytical expertise to develop robust detection methods, and the personnel to ensure processes are carried out safely and effectively. We’ve built entire programs around HPAPI development and manufacturing, so they don’t scare us!

Case Study: Hot Melt Extrusion of a Hormonal Vaginal Ring

Figure 2: A vaginal ring.

Judy: We’ve performed multiple studies over the years to verify our HPAPI containment procedures. In one case, we were approached to manufacture a hormonal vaginal ring via hot melt extrusion (Figure 2). Prior to manufacturing, we designed and implemented a complete powder containment and control system utilizing both an isolator and a ventilated shroud in our dedicated HPAPI Manufacturing Suite. A containment verification assessment was performed to evaluate the effectiveness of containment offered by the facility design, engineering controls, and the associated employee work practices within the Clean Room, Weighing Room, and Wash Room

To facilitate the assessment, we selected a surrogate API to utilize in manufacturing activities. The assessment included:

- Collection of air and surface sampling for the surrogate test compound before, during, and after the containment verification assessment

- Measurement of air temperature and relative humidity in the testing areas before and after the sampling event

- Observation of work activities

These items were evaluated during all manufacturing activities, which included weighing and transfer of API, extrusion of product, shutdown of equipment, and cleaning of the equipment and facility. The results of the assessment were compared to a predefined limit for the concentration of API as well as baseline data from the manufacturing areas. Upon passing this assessment, we felt comfortable with our containment procedures and moved forward with manufacturing the product.

Conclusion

As we’ve explored in this interview, HPAPI handling requires specialized infrastructure and highly trained personnel to properly execute. At Particle Sciences, we are experienced and confident when it comes to HPAPIs. Our staff has decades of experience working with cytotoxics, sex hormones, and other HPAPIs in a well-equipped development and manufacturing space. We’ve worked on HPAPI projects utilizing a range of formulation techniques and dosage forms, including hot melt extrusion, microparticle formulations, and milling, and our formulation scientists are supported by highly skilled analytical and quality teams to ensure your project’s success.

If you have a highly potent API, Particle Sciences has the expertise to develop it. Come be our next success story. Contact us today!

Authors: